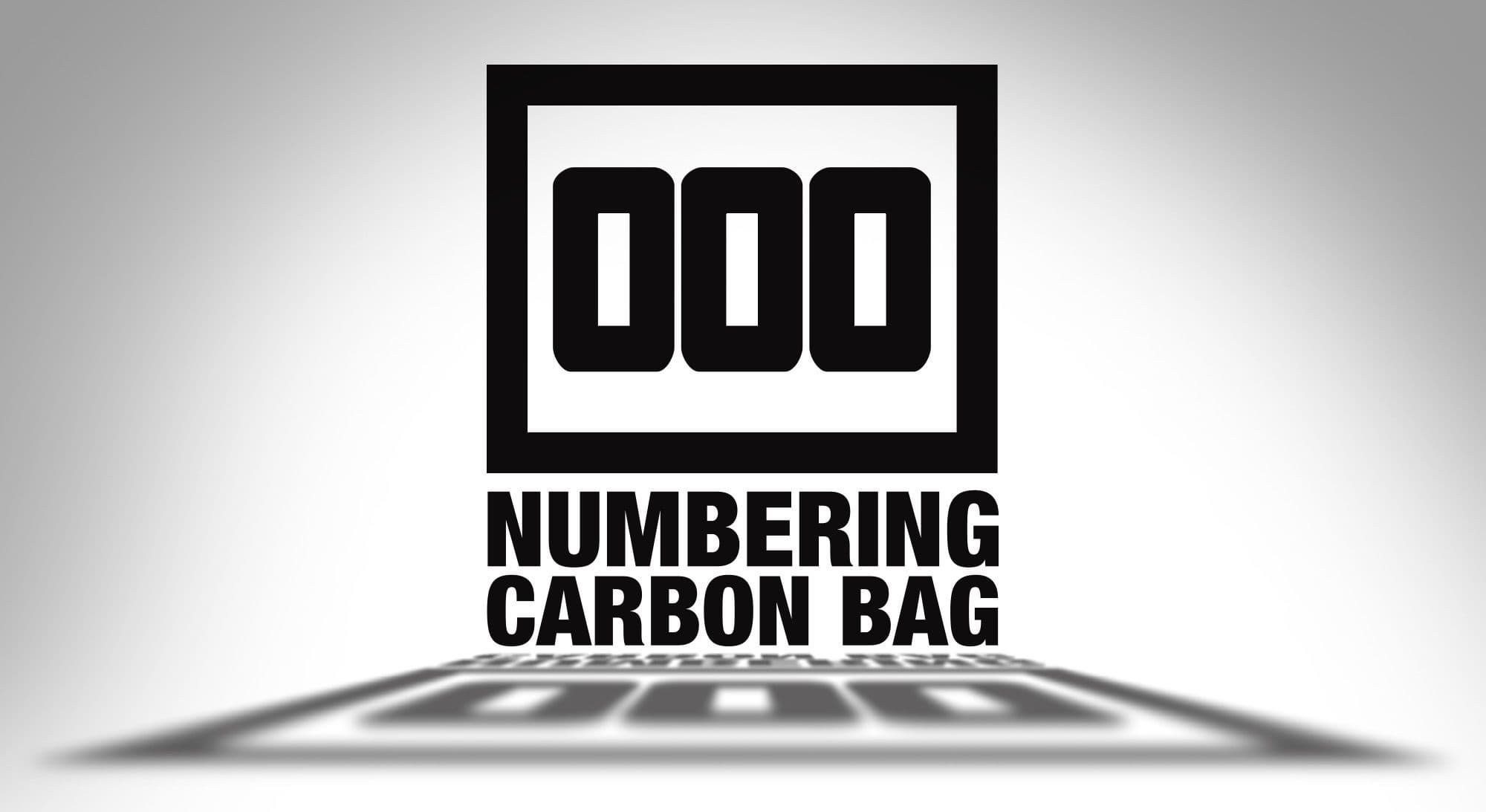

[201 Carbon Multibag] Black Hexa carbon hardshell limited

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Numbering Carbonbag

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- bag, brief case, carbon bag, carbon & carbon composite

- Category

- Bags & Luggages

MIGHTYM

- Verified Certificate

-

5

| Product name | [201 Carbon Multibag] Black Hexa carbon hardshell limited | Certification | - |

|---|---|---|---|

| Category | Bags & Luggages | Ingredients | - |

| Keyword | bag , brief case , carbon bag , carbon & carbon composite | Unit Size | 430.0 * 340.0 * 120.0 mm |

| Brand name | Numbering Carbonbag | Unit Weigh | 1600 g |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

Colors are most similar to the actual product and may look different depending on the condition of the monitor.

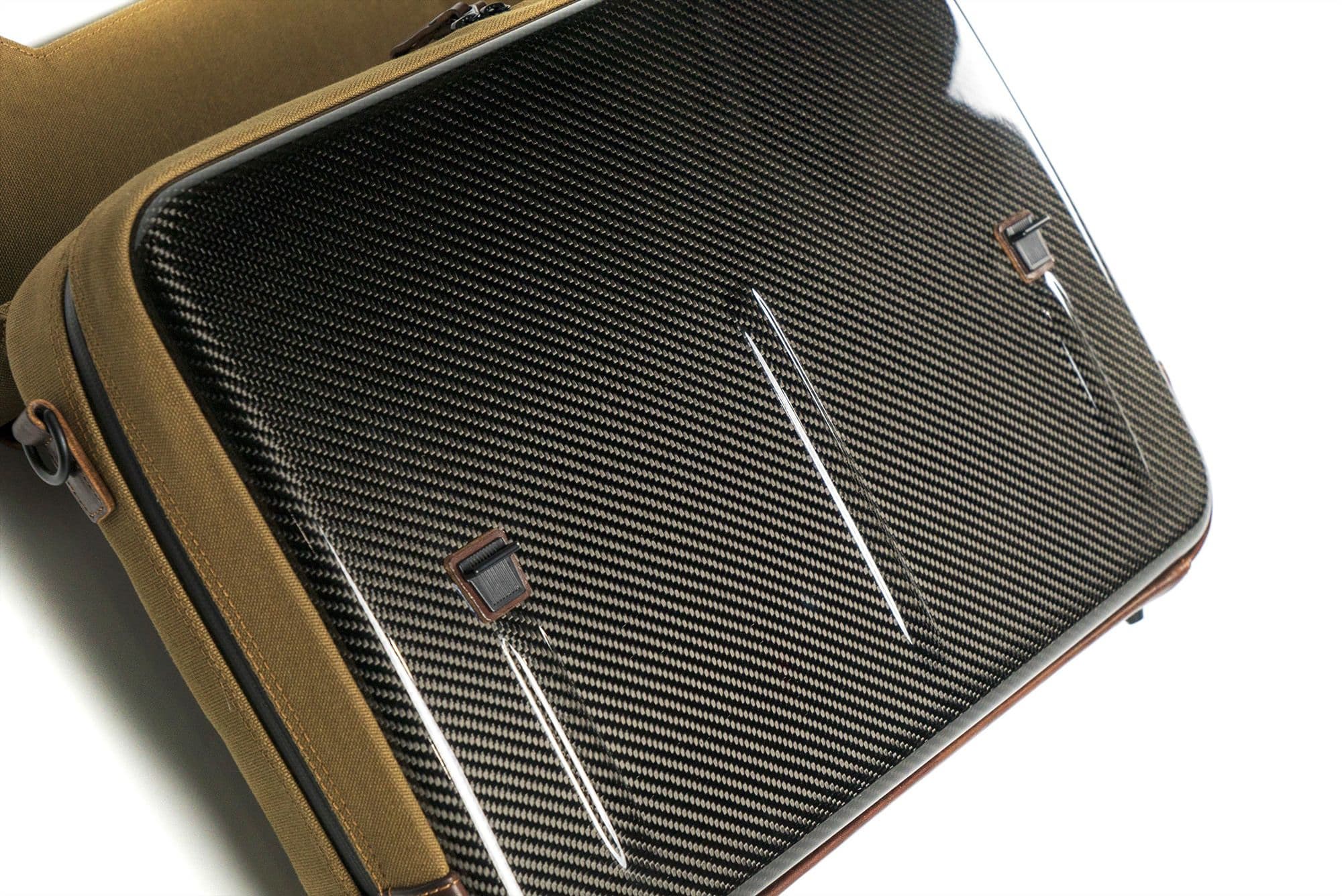

Make you stand out anytime, anywhere. Black Hexa Carbon Edition

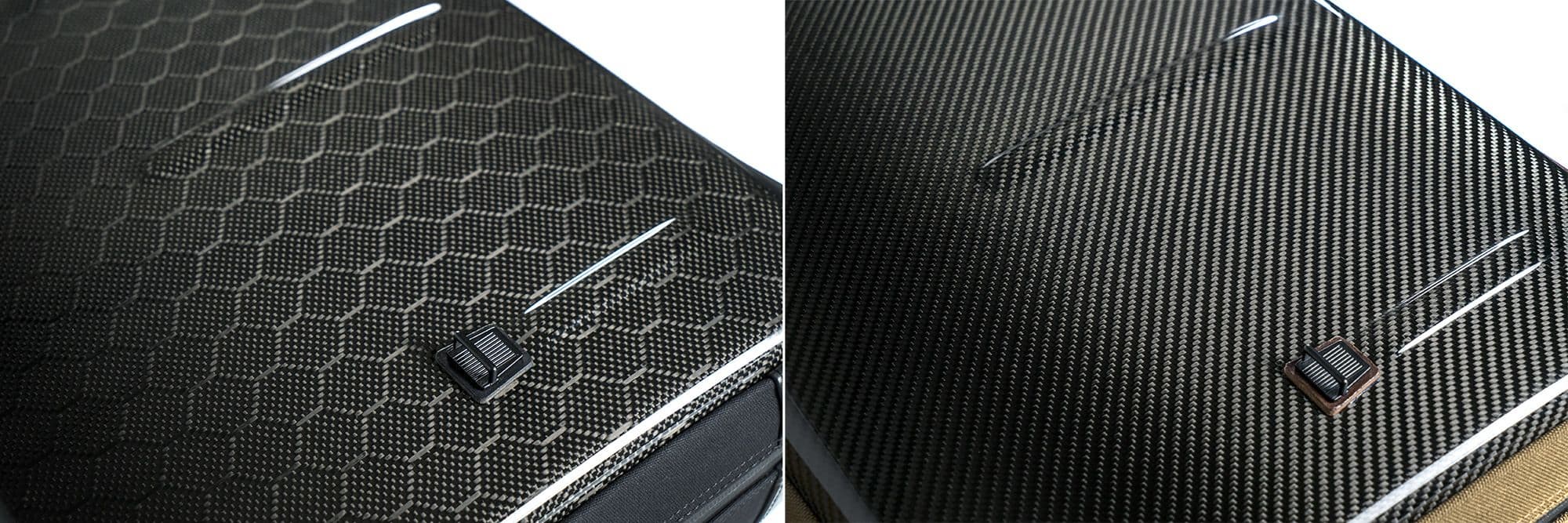

The hexa-shaped carbon fiber is a unique type of fabric. Unlike other types of carbons, the hexa-shaped carbon fiber is a unique, beautiful and high-end carbon fiber with repeated hexagonal patterns.

Only a few companies are capable of handling this fabric due to the difficult weaving process and high manufacturing costs.

The Hexa Black Edition is produced from the special carbon fiber with hexagon patterns, which is manufactured by collaborating with Hankuk Carbon Corp.

TEMPESTI ELBAMATT Black Leather, which is deep enough to be used with a heavy black canvas, always has a special Hexa carbon hardshell, an unusual pattern in carbon.

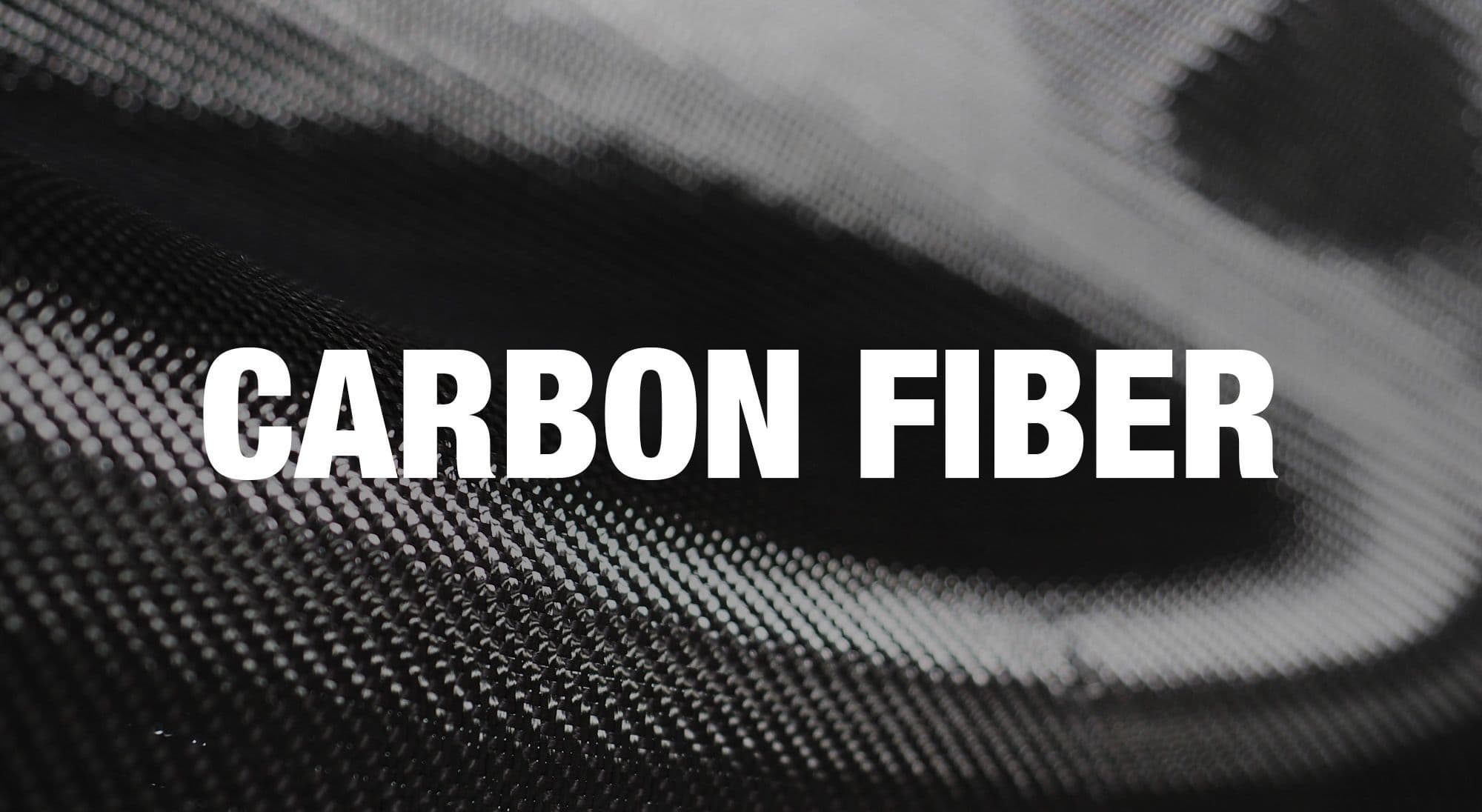

Do you know about carbon fiber called black diamond?

Superbikes run through tracks with sharp exhaust sounds, F1 race machines running at over 300 kilometers per hour, fighter jets flying at supersonic speeds, and rockets flying out into space with powerful propulsion.

There is always a material that meets the great challenge of surpassing the limits of mankind.

"That is CARBON FIBER."

Carbon fiber is a new material that many people have heard of, but most people have not encountered. It is 5 times stronger than steel and 10 times stronger than aluminum, so it can be manufactured lightly, which is why it is used in superbikes, race machines, fighter planes, and spaceships. For this reason, carbon fiber is called the “dream material”.

[The Numbering Carbon Bag Project] is Factory M's new challenge to expand such carbon fiber into everyday life.

12 years of experience in manufacturing composite materials and 35 years of experience in manufacturing luxury bags.

Factory M is a high-end motorcycle design brand that manufactures carbon products from design to packaging.

We have been designing and manufacturing composite products for the past 12 years, working to apply carbon fiber to our products, and have produced high-performance motorcycle products. One question arises as I manufacture so many different motorcycle products.

"Wouldn't it be possible to expand these high-performance materials into a wider range of fields, not just motorcycles?"

And starting with this question, we struggled to create a carbon fiber item that could be used by more people.

We recalled the F1's carbon frame, which protects the driver from accidents at speeds of up to 300 kilometers per hour.

And realized that the light and strong carbon properties match the essence of a bag that is easy to carry and protects its contents.

In order to make such a carbon hardshell bag, we have spent a lot of years thinking, designing, combining designs and developing materials for it. And in March 2019, the first numbering carbon bag project [the 109 carbon sling bag] was born.

With the attention and response we received at that time, we were able to start developing new products.

Introducing the second numbering carbon bag project, the 201 Carbon Multi Bag.

Numbering Carbon bag, "201" Carbon Multi Bag

The name also includes the identity of motor sports. Like the model name of the car's or motorcycle's engine capacity and the maximum speed, the name of the numbering carbon bag product line refers to the weight of the carbon hard shell.

The 201 Carbon Multibag's real carbon hardshell weighs just 201 grams, as its name suggests. This is possible because it is manufactured manually using only 100% carbon fiber.

Numbering Carbonbag, 201 Carbon "Multi" Bag

The 201 Carbon Multi Bag can be used in four ways. The product name is not limited to one purpose because it can be used in various ways depending on the situation.

1. in business and everyday, brief case style

The 201 Carbon Multi-Bag is designed to protect your documents and valuables with the full protection of the Carbon Hard Shell.

Similar in size to a full-sized briefcase, it can hold up to 17-inches laptops.

The simplest way to carry the handle is the light, easy-to-move way without extra straps, which is useful for everyday commuting.

Since the handle is the most frequently used part in everyday life, it is considered for durability and material touch. The handle fixed to the top of the cover is double-locked with lockstitch and dedicated rivets, and it utilizes the characteristics of TEMPESTI ELBAMATT, coated canvas and metal material to ensure excellent durability.

The supplied shoulder strap can be attached and worn as a shoulder bag or cross bag. This is more useful for everyday as well as business and business trips.

The freely adjustable shoulder straps are made of TEMPESTI ELBAMATT and Alcantara, which are both durable and comfortable to use. In particular, Alcantara-leather pads, the core of the shoulder strap, have been tested for optimal size by testing various sizes for a long time and can be moved and used to fit the body of the consumer.

2. Backpack style suitable for various situations

If you need to put heavy items such as laptops or have both hands free, you can use the two supplied backpack straps to pack in a backpack style. The freely adjustable backpack straps also use TEMPESTI ELBAMATT for increased durability, and the two straps allow for heavy weight distribution.

Ideal for designers, freelancers, and students who always need to carry heavy-weight contents such as laptops, tablets, photographing equipment, and major books.

3. Carrier subbag style, if with carrier

If you're traveling with you on a long trip or traveling abroad, you can use the back holder of the 201 Carbon Multi Bag. The back holder secured to the body is inserted into the handle of the carrier, making it firmly fixed and can be used as a subbag style of the carrier.

It is possible to reduce the inconvenience of opening the carrier by inserting passports or documents that are frequently used on business trips or trips.

It can be fixed while the shoulder strap or backpack strap is attached, so it can be easily removed and used depending on the situation.

4. Side-bag style for riding

Its high water resistance, high durability, and a carbon fiber hard shell keep its shape perfectly, making it an ideal side bag for vehicles such as motorcycles and bicycles.

By installing a universal bracket (sold separately) on transportation equipment such as motorcycles and bicycles, the 201 Carbon Multi Bag can be attached and detached with one touch.

The lower 2, center 1, upper 1, and four-point fixings are installed so there is no worry about intense riding.

Newtro design, and develop for users.

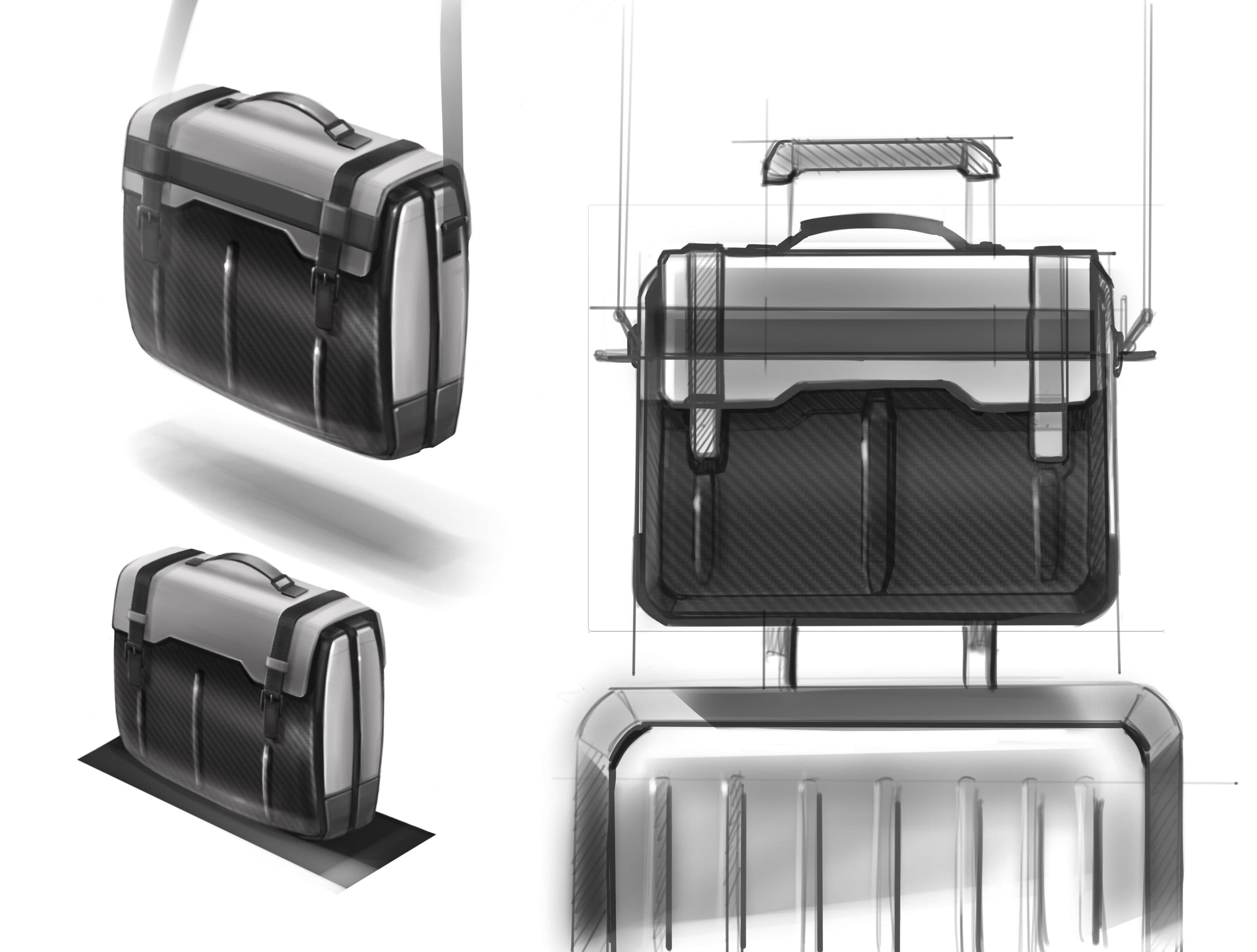

Professional industrial designers' styling and user-friendly design are the biggest advantages of Factory M, which goes from sketching to manufacturing.

The concept of Newtro design -New Retro design-, has reinterpreted the retro design using traditional materials to match the latest styling through a carbon fiber hard shell, resulting in a unique design.

The 201 Carbon Multi-Bag is designed in a unique and sophisticated style, making it ideal for any fashion and any occasion.

Design upgrades through 9 months of sample testing after product key sketches demonstrate Factory M's commitment to making not only a good looking bag, but also a bag that can be used comfortably for a long time.

Continuous design modifications through 3D design and 3D printing, as well as countless user tests and in-depth research on each of the sample upgrades, have made the 201 Carbon Multibag a comfortable and easy-to-use bag for everyone.

Perfect combination for high end products made of the best materials.

The biggest advantage of the carbon fiber hardshell is its light weight.

Perhaps every day, every hour the bag you have to carry around shouldn't be heavy, so we focused on lightening the hard shell.

The real carbon hardshell used in the 201 Carbon Multibag weighs just 201 grams, as its name suggests. It's lighter than a smartphone in your hand. This ultra-light hardshell has reduced the weight of the 201 Carbon Multibag to 1600g.

At only 1600g, the 201 Carbon Multibag weighs incredibly lighter than other brands of hardshell bags.

Compared to the famous aluminum hard shell brief case of luxury brands, about 43% lighter,

It is about 54% lighter than the semi-class hardshell briefcase made of leather, and about 24% lighter than the PC-based hardshell briefcase, which is said to be ultralight.

Light but strong. Best strength to weight ratio.

We do not guarantee the same effect in actual use environment.

CFRP (Carbon Fiber Reinforced Plastic), a composite made of carbon fiber with a special epoxy, is known to exhibit 5 times the strengths of iron and 10 times of aluminum .

For this reason, carbon fiber is used in the latest fighter aircraft, such as the F22 and F35, which fly at supersonic speeds.

It is also known that there is no fatigue accumulation which is a disadvantage of metal . One million times of aluminum and one billion times of steel end up with metal fatigue. On the other hand, carbon has been used extensively in the structural engineering of civil engineering for earthquake design and Airbus, which is famous for being the largest passenger aircraft due to their limitless fatigue life.

In addition to physical protection, carbon hard shells also have properties that prevent and reflect electromagnetic waves.

It has the effect of blocking the misuse of electronic sleeves by copying and exploiting contents related to personal information such as valuable mobile devices, passports containing NFC, and cards containing RFID chips.

It is also more beautiful than any other material.

Carbon fiber is called black diamond. Carbon fiber, which is made from carbon like diamonds that were born as the pinnacle of jewelry under the infinite pressure, has attracted attention in various fields such as fashion and high-end product design with its unique depth and beautifully woven pattern.

Carbon fiber hardshells are always present with a shiny finish to enhance the depth of beautiful patterns. The hard, smooth surface also delivers a fast and dynamic sensation that creates a futuristic impression.

However, carbon fiber composites are difficult to make.

Since 1985, it has been commercialized since supercars, but there are still no automated processes worldwide except for some simple forms.

In particular, high performance carbon products can only be made by the skilled hand of the molding specialist.

Brand Factory M, which specializes in high-end carbon products, has commercialized more than 30 motorcycle products and developed the 201 carbon multi-bag hard shell based on the accumulated data. In addition, all carbon hardshells are manufactured by a team of 12-year-old artisan technicians in our factory, with no outsourcing.

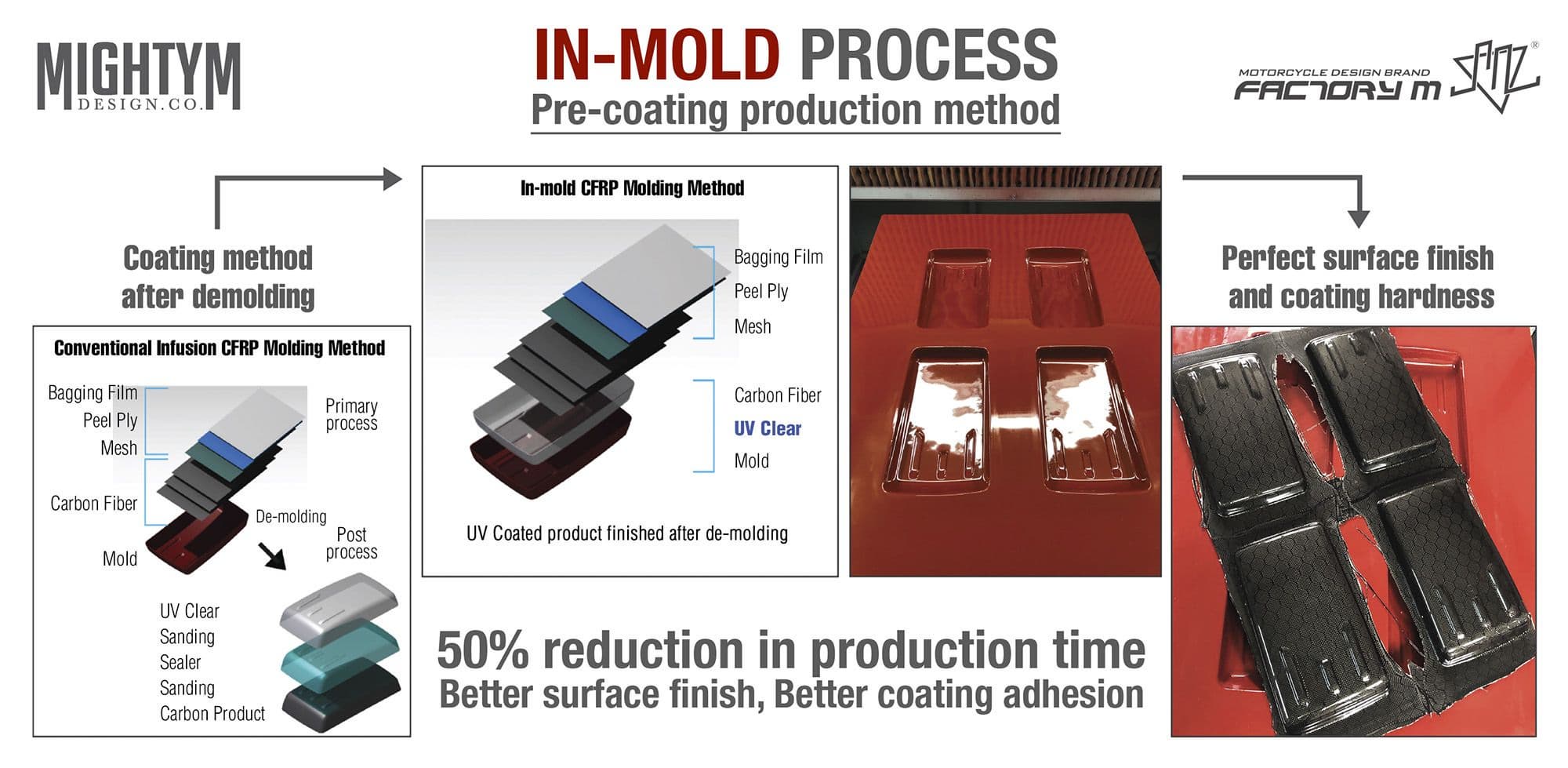

Most powerful UV-blocking, anti-scratch coating.

Factory M's unique in-mold clear pre-coating technology protects the carbon hard shell from yellowing and deterioration of properties due to aero-space grade UV protection coating.

In addition, due to the differentiated process, the adhesion between the carbon fiber hard shell and the clear coating is 4 times higher than that of the general coating method, which is as strong as the impact.

The clear coating layer with high transparency and deeper look at the beautiful pattern of carbon has superior surface hardness compared to general urethane coating using Duratec® from Hawkeye Industry, Inc. of USA. The cross-linked polymer layer also shows excellent chemical resistance.

In other words, it is not easily scratched and resistant to external pollution such as acid rain and calcium chloride, so it always looks shiny.

All materials to the same top-notch level as real carbon hard shells

We use the finest functional materials to match the level of these best carbon fiber hard shells.

All leather parts of the 201 Carbon Multi Bag use TEMPESTI ELBAMATT Whole Skin, Italy's finest wax-coated vegetable leather. ELBAMATT Whole Skin is the world's finest whole leather with wax coating for excellent water repellency and high resilience.

Likewise, the shoulder strap pads are made from Alcantara, a genuine Italian material, used in supercar seats and dashboards, with excellent wear and water repellency.

In addition, a multi-layer system is achieved by using PU waterproof coating on the finest canvas, luxury interior reinforcement and TPU-coated oxford lining. This is the M LAYERED® system, one of the key technologies of numbering carbon bags. It also shows the surface of the luxurious canvas while allowing easy management.

All of this luxury material is stitched together with carbon hard shells using Kevlar® yarn from Dupont®, which is known for its armor protection and friction for motorcycle riding gear.

From large books to 17-inch laptops. Ample interior space.

The 201 Carbon Multibag is designed to be large enough for a variety of everyday uses. The main space can hold 17-inch work laptops and large books.

Designed to hold laptops and tablets, the interior of the bag is completely covered with M LAYERED® Satin Suede, a non-animal suede developed with three levels of reinforcement to prevent scratches on electronics. The sub-pocket is also covered with M LAYERED® satin suede to keep your small items safe for scratches.

Using the physical protection and electromagnetic shielding properties of the carbon hard shell, we have created a pocket that can hold a mobile device, passport or wallet on the inner side of the hard shell with the highest protection.

The YKK one-touch breaker is applied to prevent spilling of contents or excessive body opening and the carbon hard shell touching the floor. The position can be set freely at the desired angle and can be separated with one touch for ease of use.

The best finish up to one small part

Coating process of various metal decoration is Mil-Spec class level and durable enough to be used for military firearms. It also adds waterproof zippers and zipper slides made by YKK of Japan for even more functionality. Always available with the same quality, same performance and finish.

And all of these are made through the hands of artisans.

A team of craftsman technicians who have developed and manufactured carbon composites for 12 years never compromise quality.

In addition, 35 years of experience in the manufacture of luxury bags, bag masters produce only three products a day with perfect stitching. For high quality control and perfect finishing, we boldly outsourced mass production.

It's not just a good looking bag.

All parts finished with leather are reinforced with additional webbing for increased durability. In this way, the bag master's know-how fully reinforces the invisible parts and maintains its shape without sagging even after long use.

Bag craftsmen of 35 years of experience in the manufacture of luxury bags make perfect details without missing out the details.

And we thought about the environment.

Alcantara material that has obtained TÜV SÜD carbon neutral certification in all processes from production to disposal without chemical treatment. TEMPESTI ELBAMATT is known for not slaughtering livestock for skin. Toray's carbon fiber, famous for its environmentally friendly materials. And we create everything from non-allergenic materials to pure cotton pouches wrapped in bags and stuffing paper. We continue to think about sustainable products.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

MIGHTYM

-

5

- President

- Minwoo Woo

- Address

- 27, Geochinbongi-gil, Soheul-eup, Pocheon-si, Gyeonggi-do, Korea

- Product Category

- Bags & Luggages,Motorcycle Accessories & Parts

- Year Established

- 2016

- No. of Total Employees

- 1-50

- Company introduction

-

MIGHTYM is the industrial design company which is based on motorcycle

and carbon fiber composite. With society facing a remarkable transition

on auotomotive industry, we’re aiming to bring a innovation in motorycle

culture. And we at MIGHTYM are trying to achieve it by carbon composite

product and culture service.

Company Name

MIGHTYM

Main Business

Transportation and product design / carbon composite product production

Main Product

Carbon motorcycle parts / carbon equipment

Establishment

01.07.2016

Address

27, Geochinbongi-gil, Soheul-eup, Pocheon-si, Gyeonggi-do, KR

Website

en.mightym.co.kr

Online Store

en.factorymstore.com

- Main Markets

-

France

France

Germany

Germany

Hong Kong(China)

Hong Kong(China)

Japan

Japan

Russia

Russia

Singapore

Singapore

South Korea

South Korea

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product

Related Products

DUNLOP LUGGAGE BAG

Handbag & Shoulder bag V044

Elephant Backpack

Packing Cubes 7 Pcs Travel Luggage Packing Organizers Set

korea childrens jacket

![[201 Carbon Multibag] Black Hexa carbon hardshell limited](https://web.tradekorea.com/product/13/1892013/[201_Carbon_Multibag]_Black_Hexa_carbon_hardshell_limited__2.jpg)